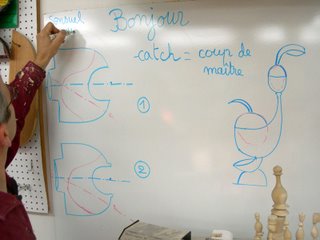

Thursday was box day in the Escoulen hands-on class. Jean-François sketched the basic principals on the board. The first project was a "sensuel" box where the base and lid were turned on two centers. The last project of the day was a double box. At the end of today I was complaining that "my brain hurts!" alá Monte Python's "Nurse! My brain hurts!"

These boxes combined all the elements that we had learned up to this point, and it was a lot of fun to work on them as well as watch Jean-François demonstrate how to do them correctly.

The sensuel box starts on center by forming the shape near the opening. The front face is trued and then the hollowing process is done.

The sensuel box starts on center by forming the shape near the opening. The front face is trued and then the hollowing process is done.

These are end-grain pieces so a spindle gouge can be used for the hollowing process.

The surface is refined with a scraper worked at a 45° angle. This scraper is very nice - it's from Australia, but I don't know the manufacturer. It looks like a circular disk with a raised rim. It cuts very cleanly and leaves a surface that doesn't need to be sanded.

The bedan is used upside down to put a small lip at the rim of the opening. The lip needs to be vertical with no taper for a proper fit.

Here's what it should look like. The next step is to move the center and do the shape of the base. You'll be able to see this with the pictures I have of the top being made.

The top begins in the same way, on center. You make a tenon to fit the base so that the lid will have a nice "pop" when the box is opened.

For these small boxes, you can go directly to the hollowing step. For large boxes, you'd do the hollowing first and then adjust the fit.

When the fit is correct, the axis is changed to the second center. We used about 10° offset from center.

The turning looks lopsided. You have to make sure you leave enough wall thickness to avoid going through the hollowed out part of the box.

Here's the finished "sensuel" box. Barbara Crockett nicknamed these to be "gonad boxes." One of the guys said they were too small to fit that description. I won't repeat the rest of that "discussion."

The second project of the day was a simple box turned on three centers to make a two-faceted box. I say, "simple," but the process takes some thought to match up the two facets of this box.

When both facet surfaces are turned, you have to go back to the first axis to center the hollow part of the box.

After facing off the front, you adjust the axis until the circle is centered. Then you can do the hollowing.

If everything looks right, the center is in the middle and the facets are of equal length.

Hollowing is the same as in the previous box. You have enough room to turn off the base and put a decent surface on the bottom. The nub is carved off and sanded. You can also do a jam chuck to put a feature on the bottom.

A lid is turned to fit the base. You can do this on multiple centers, too.

Here's the demonstration piece.

The most challenging project of the week was a double box. You start between centers and put a tenon to fit the Escoulen chuck on each end of the cylinder. Place one tenon into the chuck and part of about 1/3 of the length for the lid.

The remainder is turned off center to about an inch from the edge. You need to have enough material toward the top to turn the first box.

A cylinder is turned near the top.

The box shape is turned and most of the mass of the piece is left intact for the hollowing process.

The top box is hollowed with a ball end mill bit and then finished off with the scraper.

After the hollowing is complete, the stem of the box is turned.

And the surface for the lower box is refined. This is just like what we did in turning the "golf club" shape, except that the top is a small box rather than a narrow stem.

The base is put on an axis that maximizes the diameter of the base. Again, this is just like what we did in turning the "golf club" and spoons in the previous sessions.

The basic box shape is turned, but not completed. You need to have some mass at the base for the hollowing process, but you also need to know where the curve is going to judge the wall thickness during hollowing.

The hollowing process is the same as in the spoon, except you have a big obstacle swinging around at the top. You have to watch where your tool shaft is during hollowing, and you have to be careful in removing the tool from that shadow tube. Concentration is a must!

After the hollowing is complete, you turn a small lip at the top of the box. The bedan tool is again used for this step. It's good that you can see through the shadow line. You also have to blend the stem line into the base line. This can be done with a scraper, or you can do it off the lathe with a rasp.

The base is then completed and the piece parted off.

We nicknamed this double box, "the toilet box." Jean-François told me he had actually made one to resemble it's namesake, complete with a chain and handle for the top part of the box.

The spare piece of wood that was originally parted from the blank is used to make both lids.

One, for the lower box. . .

and one for the upper box. What a fun project!

I didn't attempt the double box project on this day, but worked on my box making skills. Here are my attempts from Day 4.

Devon was the only one of us to try the double box on Thursday, but he decided to not try the hollowing of the lower box. He had lots of help and advice in turning the base. L to R: Jean-François Escoulen, Devon Palmer, and Walt Betley.

Here's Devon with his project. Nice one, Devon.

No comments:

Post a Comment